1

Strict Process Management from the selection of resources to the complete products

To ensure that our castings always maintain high quality, we directly source and supply them from our registered domestic partners. We only use raw materials that have undergone strict and thorough verification for the production of our castings.

2

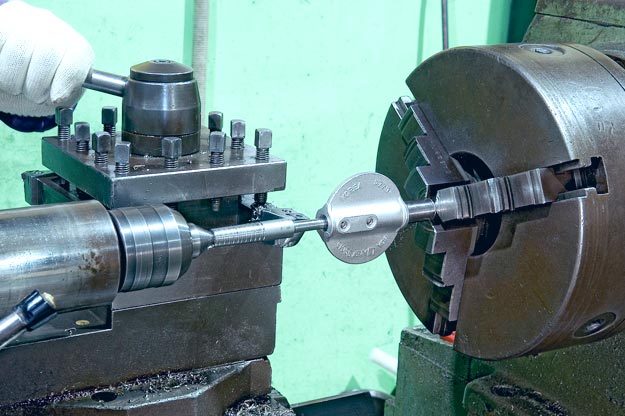

Superior Machining & Tooling Work

The machining work of HS valves is performed in CNC line with accuracy. The work lines are perfectly arranged by the characteristics and purposes of each item on the bases of our accumulated technology. For the production of the perfect quality of goods, each production line is subjected to rigorous testing and inspected by skilled inspectors to prevent possible problems or defects.

3

Accumulated Know-how & State-of-the-art Technology

Starting from the processing of raw materials, we implement thorough testing & inspection according to each work procedures and this process is continued to the semi-completed products. These semi-manufactured goods and components are carefully assembled to be as a complete unit by skilled technicians. Testing that is applied to the completed products includes 100% pressure and leakage testing, dimensional testing, non-destructive testing, eye testing, etc. At this stage, the products are test-operated in a simulated condition that is identical to the actual conditions for the perfection and completeness of quality.

4

Advanced Quality Management System

To maintain perfect quality, we have obtained the world’s most authoritative certifications, including ISO, API, CE, Fire Test, KS, and KC. We manufacture products that meet the requirements of these certifications, ensuring reliable and guaranteed quality at all times.